How 3D Printing is Revolutionizing Medicine

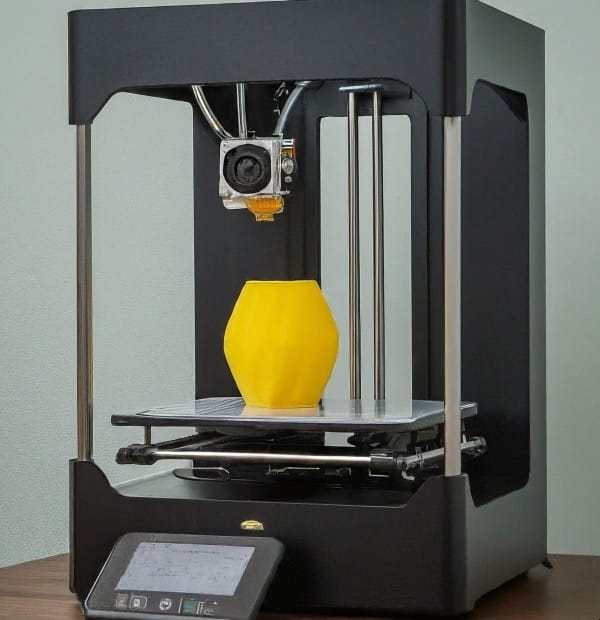

The medical field is undergoing a significant transformation fueled by technological advancements. 3D printing, once a concept relegated to science fiction, is rapidly becoming a mainstream tool with the potential to revolutionize healthcare.

This technology allows for the creation of three-dimensional objects from digital files, offering unprecedented possibilities for personalized medicine, improved surgical planning, and even the development of transplantable organs.

From Simulation to Surgery: 3D Printing in Medical Training and Planning

Surgeons traditionally rely on static images like X-rays and CT scans to plan complex procedures. However, 3D printing offers a more tangible and interactive approach. By creating physical replicas of patients' organs and bones based on their medical scans, doctors can gain a deeper understanding of the anatomy involved in a surgery. This allows for:

- Improved Visualization: A 3D printed model provides a superior perspective compared to flat 2D scans. Surgeons can manipulate the model, examine intricate details, and practice the procedure beforehand, leading to increased confidence and potentially reduced operative time.

- Enhanced Patient Communication: These models can be used to explain complex procedures to patients in a clear and concise manner. A tangible representation can significantly improve patient understanding and informed consent.

- Reduced Risk of Complications: Practicing surgeries on precise replicas can help identify potential challenges and plan for contingencies. This reduces the risk of intraoperative complications and improves patient outcomes.

A study published in the Journal of Medical Simulation found that surgeons who utilized 3D printed models for preoperative planning reported a significant increase in their confidence and a decrease in anticipated surgical difficulty.

Custom Software Development Services

Work with our in-house Project Managers, Software Engineers and QA Testers to build your new custom software product or to support your current workflow, following Agile, DevOps and Lean methodologies.

Printing the Future: 3D Printing in Medical Devices and Implants

The applications of 3D printing extend beyond surgical planning. Medical device manufacturers are increasingly leveraging this technology to create customized implants and prosthetics. Traditional implants are often manufactured in standard sizes, which may not perfectly match every patient's anatomy. 3D printing allows for the creation of:

- Customized Implants: Using patient-specific data, 3D printers can create implants that precisely fit the unique anatomy of each individual. This leads to improved functionality, reduced recovery times, and a lower risk of rejection.

- Biocompatible Materials: Advancements in bioprinting allow for the use of materials that are compatible with the human body. This opens doors for the creation of implants that integrate seamlessly with a patient's bone or tissue.

- Complex Prosthetic Designs: 3D printing facilitates the design and production of intricate prosthetic limbs that offer greater functionality and improved aesthetics for amputees.

A 2020 report by Grand View Research valued the global medical 3D printing market at USD $14.1 billion and projects it to reach USD $40.8 billion by 2027. This significant growth signifies the increasing adoption of 3D printing technology within the medical device industry.

Printing the Unimaginable: 3D Printing and the Future of Transplants

The holy grail of 3D printing in medicine lies in the potential to create transplantable organs. The current organ transplant system faces numerous challenges, including a critical shortage of donor organs and the risk of organ rejection. 3D printing offers a glimmer of hope by:

- Bioprinting Organs: Researchers are working on bioprinting techniques that utilize stem cells and biocompatible materials to create functional organ tissues. While significant hurdles remain, this technology holds the promise of alleviating the organ donor shortage in the future.

- Vascularization Challenges: A major obstacle in bioprinting organs is the development of a functioning vascular network to supply blood and nutrients to the newly created tissue. Researchers are actively exploring solutions to overcome this challenge.

- Personalized Transplants: 3D bioprinting could one day allow for the creation of organs that are genetically matched to the recipient, eliminating the risk of rejection. This would revolutionize the field of transplantation and offer new hope to patients with organ failure.

While 3D printed organs remain a future prospect, the potential impact on the field of transplantation is undeniable. With continued research and development, this technology could revolutionize how we treat patients with organ failure.

Beyond the Hype: Challenges and Considerations for 3D Printing in Medicine

Despite the immense potential of 3D printing in medicine, there are challenges that need to be addressed. These include:

- Standardization and Regulation: As the technology evolves, establishing standardized protocols and regulatory frameworks is crucial to ensure the safety and efficacy of 3D printed medical devices.

- Cost Considerations: 3D printing equipment and materials can be expensive, potentially limiting accessibility for some healthcare institutions. Optimizing printing processes and developing cost-effective materials are key considerations for wider adoption.

Custom Software Development Services

Work with our in-house Project Managers, Software Engineers and QA Testers to build your new custom software product or to support your current workflow, following Agile, DevOps and Lean methodologies.

Conclusion

3D printing is rapidly transforming the medical landscape, offering a plethora of benefits for patients, surgeons, and the healthcare industry as a whole. From improved surgical planning and customized implants to the potential for bioprinted organs, this technology holds immense promise for the future of medicine.

However, navigating the path forward requires addressing challenges like standardization, regulation, and cost considerations. Collaboration between researchers, medical professionals, and technology developers is essential to ensure the safe and effective integration of 3D printing into mainstream healthcare.

As a trusted partner with extensive experience in software and business growth, 4Geeks is well-positioned to assist medical institutions and device manufacturers in harnessing the power of 3D printing. We offer a comprehensive suite of services, from designing and optimizing 3D printing workflows to navigating regulatory hurdles and developing sustainable business models.

Together, we can unlock the full potential of 3D printing and revolutionize the way we deliver medical care. With continued innovation and collaboration, the future of medicine promises to be a world transformed by 3D printing, where personalized care and improved patient outcomes become a reality.

FAQs

How does 3D printing benefit medical procedures?

3D printing in medicine allows for the creation of customized medical devices, implants, and even tissues tailored to individual patients' needs. It enables faster production, reduces costs, and offers improved precision compared to traditional manufacturing methods. By using patient-specific data, medical professionals can optimize treatment plans and enhance patient outcomes.

What are some specific applications of 3D printing in healthcare?

3D printing is revolutionizing various aspects of healthcare, including prosthetics, surgical planning, anatomical models, and drug delivery systems. It facilitates the production of complex structures that are challenging to create with conventional methods, such as patient-specific implants, biocompatible materials, and organ replicas for surgical training and patient education. Moreover, it enables rapid prototyping and iteration, accelerating innovation in medical device development.

What are the limitations and challenges of 3D printing in medicine?

While 3D printing offers numerous advantages, it also faces certain limitations and challenges. These include regulatory hurdles, such as obtaining approval for medical devices and ensuring quality control and standardization. Additionally, issues like material biocompatibility, sterilization, and post-processing may affect the suitability of 3D-printed products for clinical use. Moreover, the scalability and cost-effectiveness of 3D printing in mass production scenarios remain areas of ongoing research and development.